Why architects should choose warm edge spacers for energy-efficient designs

June 25, 2025When it comes to sustainability and energy efficiency, there is no single answer to what sustainable buildings of the future... Read more

Tel: +44 02476 639931

Email: ukenquiries@edgetechig.com

Orders: ukorders@edgetechig.com

When it comes to sustainability and energy efficiency, there is no single answer to what sustainable buildings of the future... Read more

An ambitious office development in Paris has become the latest project to benefit from Quanex company Edgetech’s world-leading Super Spacer®... Read more

Super Spacer® warm edge technology from Quanex company Edgetech, has played a key role in two of Danish architect Bjarke... Read more

For insulated glass unit (IGU) manufacturers, automation is becoming an essential step in improving efficiency, increasing capacity, and maintaining high-quality... Read more

A 15-year partnership between leading warm edge technology pioneer Edgetech, a Quanex company, and Padiham Glass has played a big... Read more

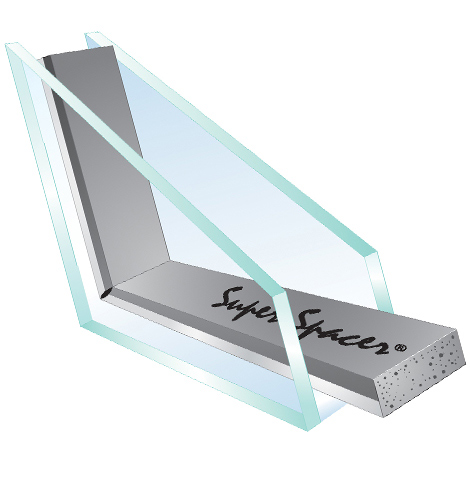

Thermal spacer bars play a key role in today's double glazing systems. The science behind them helps improve energy efficiency... Read more

Exploring how warm edge spacers are used in today's glazing is interesting. These spacers help make windows more energy-efficient by... Read more

The evolution of window technology has brought us to a crucial crossroads in the insulated glass unit (IGU) industry. As... Read more

Thermal spacer bars are a vital component of double glazing, ensuring optimal energy efficiency and enhancing overall performance. Modern warm... Read more

Foam insulation tape is a versatile and reliable solution that seals gaps, stops drafts, and improves energy efficiency in both... Read more

The Science Behind Warm Edge Spacers Warm edge spacers help reduce heat loss. This problem is common in regular windows... Read more

In an era where energy costs continue to soar and environmental consciousness is at an all-time high, UK homeowners are... Read more

Please fill out the form below to a find a local supplier. Once we've found you closest suppliers you will be able to contact them all.

Your enquiry has been successfully submitted. You should receive an email or callback with 24-48 hours.

Return to the homepage