Sign-In or Create an Account to find your purchasing solution

Become a registered Edgetech partner to start using our latest insulating technology in your glazing systems.

Tel: +44 02476 639931

Email: ukenquiries@edgetechig.com

Orders: ukorders@edgetechig.com

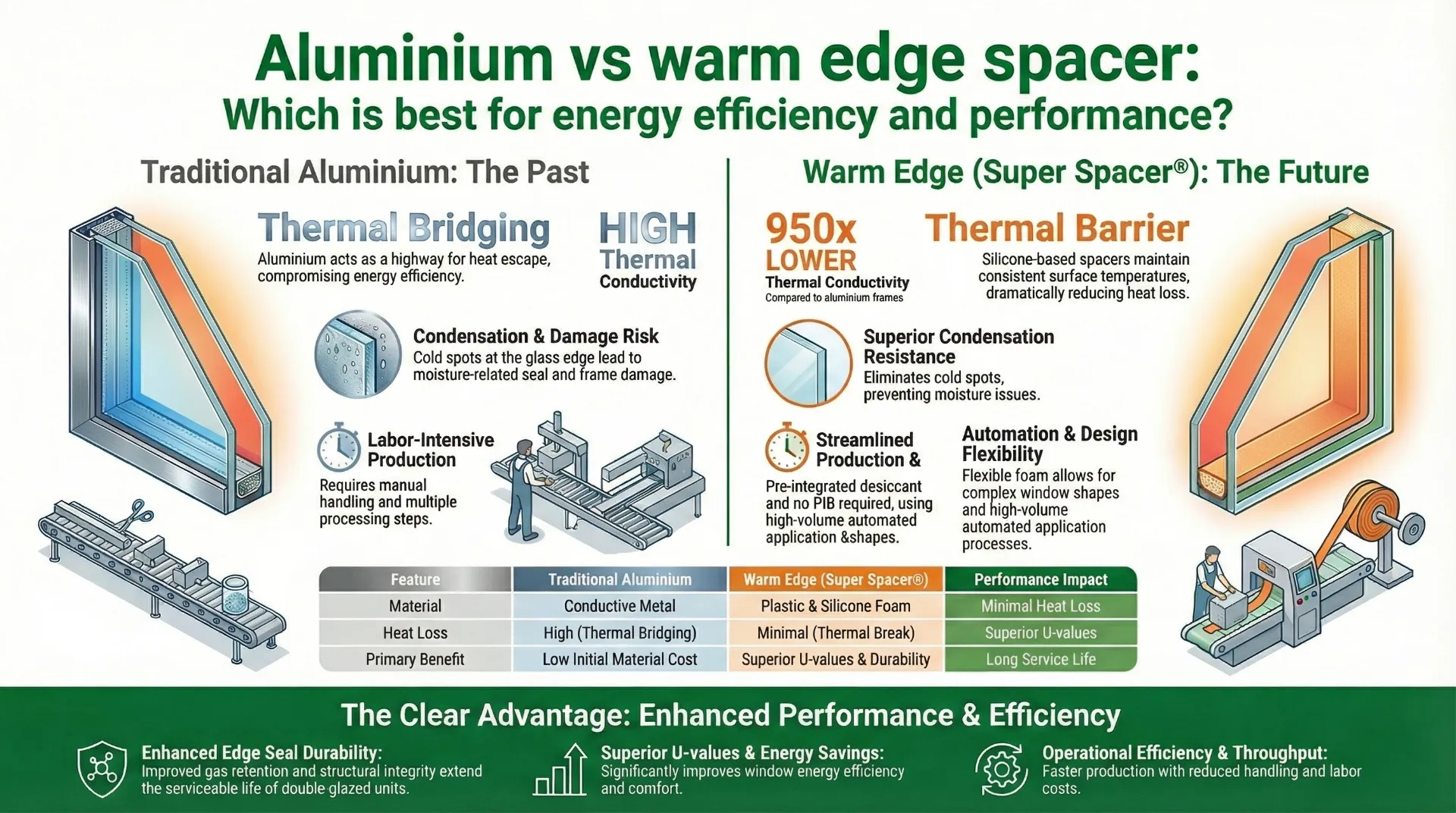

The evolution of window technology has brought us to a crucial crossroads in the insulated glass unit (IGU) industry. As energy efficiency becomes increasingly important, the choice between traditional aluminium spacers and modern warm edge technology can significantly impact a window’s performance. Read on into this comparison to understand which option delivers superior results.

Before we compare aluminium vs warm edge spacer technology, it’s essential to understand what spacers do. Spacer bars are small, thin rectangular strips separate glass panes in an insulating glass unit, maintaining the crucial gap that provides insulation. However, their role extends far beyond structural purposes and simply keeping panes apart – they contribute to the performance of the finished window.

Aluminium spacers in insulated glass units (IGUs) provided adequate structural stability and were cost-effective to produce, but their inherent properties created significant performance issues. The main challenge stems from aluminium’s high thermal conductivity, which creates a thermal bridge at the edge of glass – essentially a highway for heat to escape.

This thermal bridging effect leads to multiple problems. In winter, heat rapidly transfers through the aluminium spacer, creating cold spots around window frames and significantly increasing heating costs. These cold areas are prone to condensation formation, which can damage window seals and frames over time. The increased heat loss also reduces overall window efficiency, resulting in higher energy costs for homeowners and businesses.

Despite their structural benefits, these thermal performance limitations make aluminium spacers increasingly unsuitable for modern energy-efficient building requirements.

Warm edge spacer technology, pioneered by Edgetech with Super Spacer®, represents a quantum leap in window performance, significantly lowering thermal conductivity, enhancing energy efficiency, providing better condensation resistance and improving durability. It’s made of plastic and silicone rather than metal, which means it offers much better thermal performance.

The scientific comparison between traditional aluminium spacers and warm edge technology reveals stark differences in thermal performance. When Edgetech revolutionised the industry in 1989 with Super Spacer®, the world’s first flexible foam spacer bar, they introduced a groundbreaking combination of plastics and silicone that transformed window efficiency.

The numbers are remarkable: warm edge spacers demonstrate thermal conductivity rates that are up to 950 times lower than traditional aluminium spacers. This dramatic reduction in heat loss translates directly into improved U-values for the entire window system, significantly enhancing overall energy efficiency.

This superior thermal performance has practical implications beyond energy savings. The science of condensation formation is directly linked to temperature differentials across window surfaces. Traditional aluminium spacers, due to their high thermal conductivity, create cold spots around the edge of glass units. These cold areas become prime locations for condensation formation when warm indoor air meets the cooler glass surface.

In contrast, warm edge technologies superior thermal resistance maintains more consistent temperatures across the window surface, dramatically reducing condensation risk. This not only improves indoor comfort for homeowners but also extends window lifespan by preventing moisture-related issues that can damage seals and frames over time.

In double glazing applications, the choice of spacer bar plays a crucial role in determining the overall performance of insulated glass units (IGUs). The spacer’s effectiveness directly influences thermal insulation properties, with warm edge technology significantly outperforming traditional aluminium options.

Additionally, modern warm edge spacers like Super Spacer® excel in gas retention between glass panes, maintaining the insulating properties of gas-filled units for longer periods. The superior edge seal durability of warm edge spacers ensures better long-term performance, reducing the risk of seal failure and extending the serviceable life of double glazed units. This combination of benefits makes warm edge technology the superior choice for modern double glazing applications.

Window manufacturers gain significant operational advantages when working with warm edge technology. Products like Super Spacer® streamline the manufacturing process through simplified installation procedures. The spacer’s pre-integrated design, including built-in desiccant and no need for PIB application, dramatically reduces handling time and labour costs. The flexible nature of warm edge spacers also offers greater design freedom, allowing manufacturers to create complex window shapes and meet diverse architectural requirements without compromising performance. This flexibility, combined with efficient installation processes, helps manufacturers optimise production while maintaining high-quality standards.

Condensation – Edgech technology reduces condensation for a healthier interior environment. Designed to trap moisture out of a building, Edgetech products are an integral part of the drive towards sustainability.

The environmental advantages of warm edge technology extend far beyond immediate performance benefits. By significantly reducing heat loss and improving thermal efficiency, warm edge spacers like Super Spacer® play a crucial role in lowering building carbon emissions and reducing energy consumption. The manufacturing process itself is designed with sustainability in mind, using environmentally conscious materials and production methods.

When implemented across entire buildings, warm edge technology contributes to enhanced overall building efficiency, helping property owners meet increasingly stringent environmental regulations while reducing their carbon footprint.

As well as the Super Spacer®, Edgetech’s innovative range includes specialised Super Spacer® products designed for specific applications. The Super Spacer® TriSeal™, engineered specifically for commercial buildings, features a revolutionary triple-seal design that sets new standards in performance and efficiency.

The system’s inner acrylic adhesive seal enables immediate handling of units, eliminating production delays. Its second layer incorporates a polyisobutylene seal, crucial for retaining gas in high-performance commercial IGUs, ensuring optimal thermal efficiency. The outer silicone seal completes the system, providing exceptional structural strength and long-term durability. Super Spacer® TriSeal™ has proven its worth in prestigious projects worldwide, demonstrating its reliability in even the most demanding architectural applications.

For manufacturers seeking automation solutions, Edgetech offers Super Spacer® T-Spacer™, which delivers the same superior performance as TriSeal™ but is specifically optimised for automated application processes, enabling efficient, high-volume production without compromising on quality.

Automation represents the next major evolution in IGU manufacturing, promising to transform production efficiency and quality standards. While many manufacturers currently rely on manual or semi-automatic spacer application processes, the shift towards fully automated systems presents several advantages. By investing in advanced automation technology, manufacturers can dramatically increase production capacity while ensuring consistent, high-quality results with significantly reduced labour requirements. The combination of automated processes and superior warm edge products allows for unprecedented precision and efficiency in IGU production.

The industry continues to evolve beyond automation, with warm edge technology leading the charge in material innovation and performance enhancement. New developments in materials science are pushing the boundaries of thermal efficiency, while innovative application methods are opening greater possibilities up for customisation and design flexibility.

Edgetech remains at the forefront of these developments, consistently investing in research and development to drive the industry forward. Our commitment to innovation will continue to meet the evolving needs of IGU manufacturers and the construction industry. This dedication to advancement helps maintain our position as industry leaders while supporting manufacturers in meeting increasingly demanding performance and sustainability requirements.

The comparison between aluminium and warm edge spacers clearly demonstrates the superiority of modern warm edge technology. With products like Super Spacer® leading the industry, the benefits of choosing warm edge technology are undeniable:

For IGU manufacturers, window manufacturers, and ultimately homeowners, the choice of warm edge technology represents an investment in quality, performance, and sustainability. As building regulations continue to tighten, and energy efficiency becomes increasingly crucial, warm edge spacer technology stands as the clear choice for modern window systems.

Edgetech are a Quanex company, so contact our experienced team today to learn more about how our Super Spacer® products can enhance your IGU manufacturing process and deliver superior results for your customers.

Please fill out the form below to a find a local supplier. Once we've found you closest suppliers you will be able to contact them all.

Your enquiry has been successfully submitted. You should receive an email or callback with 24-48 hours.

Return to the homepage