Sign-In or Create an Account to find your purchasing solution

Become a registered Edgetech partner to start using our latest insulating technology in your glazing systems.

Tel: +44 02476 639931

Email: ukenquiries@edgetechig.com

Orders: ukorders@edgetechig.com

If you fabricate, specify or install IGUs, you’ll know how often warm edge spacer bars, thermal breaks and window U-values come up in conversations with customers, system companies and building control.

The question behind all of that is simple:

Are thermal spacer bars genuinely worth specifying – commercially and technically – or are they just a “nice-to-have” upsell?

This article takes a practical, B2B-focused look at thermal spacer bars: how they work, how Edgetech’s warm edge solutions contribute to system performance and compliance, and what they deliver in terms of call-back reduction, specification confidence and long-term customer value.

A modern double or triple glazed insulating glass unit (IGU) typically consists of:

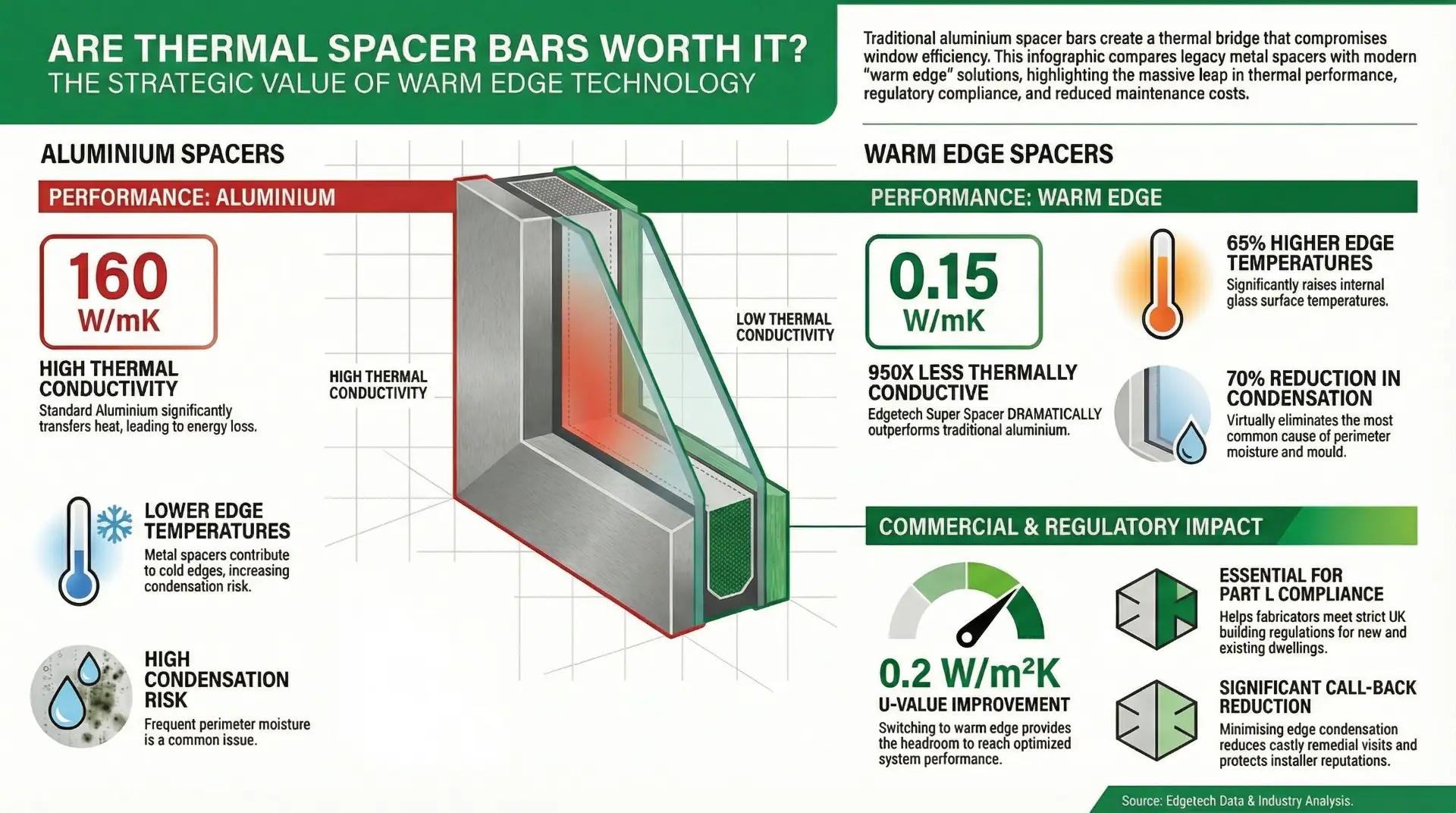

Historically, spacer bars have been manufactured from aluminium. Aluminium offers strength and ease of processing, but it is also a highly thermally conductive metal. Standard materials data put aluminium’s thermal conductivity at around 160 W/mK. In an IGU, that means the spacer acts as a thermal bridge between the warm interior and cold exterior.

The result is familiar to anyone who has modelled IGU performance:

Warm edge spacer bars are engineered to remove this weak point. Instead of metal, they use low-conductivity materials such as silicone foam, thermoplastics or composite laminates. Edgetech’s flexible Super Spacer® range, for example, has a tested thermal conductivity of around 0.15 W/mK and has been shown to be over 950 times less conductive than aluminium. That dramatic difference in conductivity directly improves edge performance.

According to EN ISO 10077, a spacer is considered “thermally improved” or “warm edge” when the product of its thickness and thermal conductivity (Σ d·λ) is ≤ 0.007 W/K. This criterion comes from the European standard, not from any one manufacturer. Edgetech’s warm edge systems, including Super Spacer, are designed and tested to meet or exceed this warm edge classification.

For IGU manufacturers and window fabricators, spacer choice is therefore not just a component decision – it is a fundamental design choice that sets the thermal performance ceiling of the entire system.

Window performance is expressed via U-values (W/m²K), but behind every headline figure is a combination of:

Traditional aluminium spacer systems drive Ψ-values up because the spacer creates a cold strip around the perimeter. In some aluminium-spacer configurations, testing shows that the majority of energy loss through the IGU occurs at this edge zone, not through the centre of the glass.

Replacing metal spacers with warm edge spacer bars:

Independent modelling and manufacturer data indicate that switching from aluminium to warm edge spacer bars typically delivers around 0.15–0.2 W/m²K improvement in whole-window U-values, with “up to 0.2 W/m²K” realistic in optimised configurations.

From a B2B perspective, that translates into:

In other words, thermal spacer bars give you extra performance “headroom” that is difficult to achieve elsewhere without redesigning the whole system.Advantages of Using Warm Edge Spacer Bars

For many installers, condensation at the glass edge is a persistent customer complaint. It can lead to:

Condensation occurs when the internal glass surface temperature drops below the dew point of the indoor air. Aluminium spacer bars, with their high thermal conductivity, reduce edge temperatures and make this more likely.

Edgetech’s warm edge spacer systems improve this significantly. Comparative testing and thermal modelling show that Super Spacer can:

For trade professionals, the implications are clear:

Instead of spending time explaining why “a bit of condensation is normal”, warm edge spacer bars allow you to offer a specification that genuinely minimises the risk at the design stage.

Manual worker assembling PVC doors and windows. Manufacturing jobs. Selective focus. Factory for aluminum and PVC windows and doors production.

The spacer bar is integral to the edge seal system and long-term performance of the IGU. Its behaviour under thermal and mechanical stress affects gas retention and the risk of premature failure.

High-quality warm edge spacer systems, as used across Edgetech’s range, contribute to durability by:

While real-world lifespans depend on design, manufacturing quality and installation, specifying a proven warm edge spacer system is a straightforward way for IGU manufacturers and fabricators to:

Protect their reputation for long-lasting units

Reduce the probability of premature misting and warranty claims

Offer more robust performance guarantees to their trade and commercial customers

Today’s warm edge spacer bars cover a range of technologies, allowing specifiers to select systems matched to project priorities and production methods.

Silicone foam spacers

Rigid thermoplastic spacers

Composite laminate spacers

Across these categories, the common objectives are:

For specifiers, the takeaway is that warm edge technology is mature, widely adopted and available in multiple formats within the Edgetech portfolio, making it straightforward to integrate into almost any frame system or project requirement.

Building Regulations are increasingly driving glazing specifications. Under Approved Document L for England (2021 edition with subsequent amendments), residential windows must meet demanding U-value targets set by government, not by manufacturers.

Key figures from Part L include:

New dwellings

Notional window U-value: 1.2 W/m²K

Limiting window U-value: 1.6 W/m²K

Existing dwellings (replacements)

Maximum window U-value: 1.4 W/m²K, or Window Energy Rating (WER) Band B or better

Most systems on the market aim to comfortably meet or exceed the notional 1.2 W/m²K value for new build, and high-performance configurations can deliver window U-values in the 0.8–1.0 W/m²K range, particularly with triple glazing.

Warm edge spacer bars from Edgetech are a key part of the compliance toolkit:

They help system houses and fabricators hit target U-values without resorting to extreme glazing or frame specifications

They create headroom for design flexibility, such as larger glazed areas or particular frame aesthetics

They support future-proofing as regulations continue to tighten and as designers work towards net-zero-aligned building envelopes

For commercial clients, social housing providers and volume housebuilders, warm edge spacer bars therefore underpin portfolio-wide compliance strategies, not just individual window upgrades.

On a component level, warm edge spacer bars represent a modest additional cost over aluminium. The real question is what that buys the trade in return.

Commercial advantages include:

Stronger product proposition

Reduced after-sales costs

Simplified compliance

End-user value story

Viewed over the life cycle of a product range or a project, thermal spacer bars are less an “optional upgrade” and more a strategic specification choice enabling better margins, reduced risk and stronger long-term customer relationships.

Super Spacer® technology represents the pinnacle of Edgetech’s warm edge innovation. First introduced in 1989, it pioneered flexible foam spacer technology and has been refined through decades of testing and field use.

Key points from Edgetech’s Super Spacer data:

For fabricators and specifiers who want a warm edge solution with a long track record and extensive independent verification, Super Spacer sits at the top of the performance range.

Get In Touch

Aluminium spacers have very high thermal conductivity (~160 W/mK), creating a cold bridge. Warm edge spacer bars use low-conductivity materials (e.g. silicone foam, thermoplastics, composites) with conductivities down around 0.15 W/mK in the case of systems like Super Spacer, and are designed to meet EN ISO 10077 warm edge criteria (Σ d·λ ≤ 0.007 W/K).

In most double and triple glazing configurations, moving from aluminium to warm edge spacer bars delivers around 0.15–0.2 W/m²K improvement in whole-window U-values, with “up to 0.2 W/m²K” achievable in optimised scenarios. This gain often provides the margin needed to reach specific Part L targets.

They don’t remove indoor humidity issues, but they substantially reduce the risk of condensation at the glass edge by lifting internal surface temperatures. In comparative testing, warm edge systems show up to 70% reduction in condensation occurrence and much warmer edge temperatures than aluminium. This translates into fewer visual issues and fewer call-backs for installers.

Yes. Warm edge spacer bars are widely used in triple glazed IGUs, curtain walling and large-format glazing. In fact, the greater the glazed area and edge length, the more important edge performance becomes. Warm edge spacers help maintain consistent thermal performance across these larger assemblies.

It is both. Warm edge spacer bars deliver a measurable technical benefit in U-values, condensation resistance and edge seal performance, and at the same time provide a clear marketing story around comfort, efficiency and Building Regulations compliance. For most trade businesses, they form part of a standard higher-value specification, not just an optional “upgrade”.

Please fill out the form below to a find a local supplier. Once we've found you closest suppliers you will be able to contact them all.

Your enquiry has been successfully submitted. You should receive an email or callback with 24-48 hours.

Return to the homepage