Why architects should choose warm edge spacers for energy-efficient designs

June 25, 2025When it comes to sustainability and energy efficiency, there is no single answer to what sustainable buildings of the future... Read more

Tel: +44 02476 639931

Email: ukenquiries@edgetechig.com

Orders: ukorders@edgetechig.com

When it comes to sustainability and energy efficiency, there is no single answer to what sustainable buildings of the future... Read more

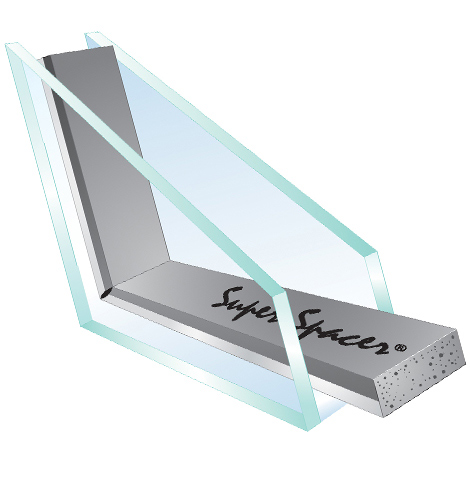

Thermal spacer bars play a key role in today's double glazing systems. The science behind them helps improve energy efficiency... Read more

Exploring how warm edge spacers are used in today's glazing is interesting. These spacers help make windows more energy-efficient by... Read more

The evolution of window technology has brought us to a crucial crossroads in the insulated glass unit (IGU) industry. As... Read more

In an era where energy costs continue to soar and environmental consciousness is at an all-time high, UK homeowners are... Read more

Warm edge spacer technology has become a cornerstone of modern window design. As the demand for thermally efficient products continues... Read more

Edgetech's revolutionary Super Spacer celebrates its 35th anniversary this year, marking over three decades of transforming the fenestration industry with... Read more

Quanex Building Products Corporation (NYSE: NX) (“Quanex” or the “Company”), parent company of Edgetech and Liniar, today announced that shareholders... Read more

Talk about thermally efficient glazing, and minds naturally jump to what windows are made of – the glass, the frame,... Read more

Quanex company Edgetech have spent decades making buildings more thermally efficient – and in doing so, have helped cut carbon... Read more

Edgetech has marked a successful return to the world's premier fenestration trade show, Fensterbau Frontale. Fensterbau attracts thousands of glass and... Read more

Martin Thurley, Managing Director of Liniar, has announced his decision to resign from his position to pursue other interests, following... Read more

Please fill out the form below to a find a local supplier. Once we've found you closest suppliers you will be able to contact them all.

Your enquiry has been successfully submitted. You should receive an email or callback with 24-48 hours.

Return to the homepage