Georgian Bars: The ultimate explainer

March 23, 2022What are Georgian bars? Georgian bars are bars fitted to windows to give them a Georgian style. They can be... Read more

Tel: +44 02476 639931

Email: ukenquiries@edgetechig.com

Orders: ukorders@edgetechig.com

What are Georgian bars? Georgian bars are bars fitted to windows to give them a Georgian style. They can be... Read more

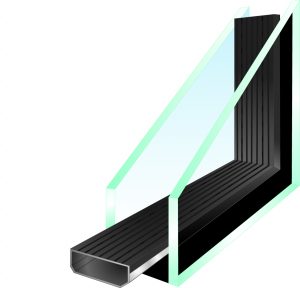

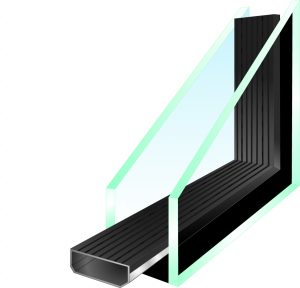

TruPlas is the rigid, glass reinforced thermoplastic spacer bar from Edgetech UK. TruPlas has been cleverly designed for increased stability... Read more

Edgetech UK, a Quanex company, has made it even easier for glass manufacturers to make better IGUs with the launch... Read more

Following Synseal's acquisition of the business and assets of Prospect Inc. Ltd trading as Systems Glass to create Global Glass... Read more

Edgetech UK, a Quanex company, launches TruPlas SDL. This is a new Simulated Divided Lite system that gives more choice... Read more

Brian McDonald, Commercial Manager at Global Glass explains: "we've been manufacturing units incorporating Super Spacer for almost 2 years now... Read more

Following release at the FIT show, Edgetech, a Quanex company, is pleased to officially launch the new TruPlasTM rigid spacer,... Read more

Please fill out the form below to a find a local supplier. Once we've found you closest suppliers you will be able to contact them all.

Your enquiry has been successfully submitted. You should receive an email or callback with 24-48 hours.

Return to the homepage