Sign-In or Create an Account to find your purchasing solution

Become a registered Edgetech partner to start using our latest insulating technology in your glazing systems.

Tel: +44 02476 639931

Email: ukenquiries@edgetechig.com

Orders: ukorders@edgetechig.com

Warm edge pioneer Edgetech, a Quanex company, has played a major part in the thin triple solution that is set to revolutionise triple glazing.

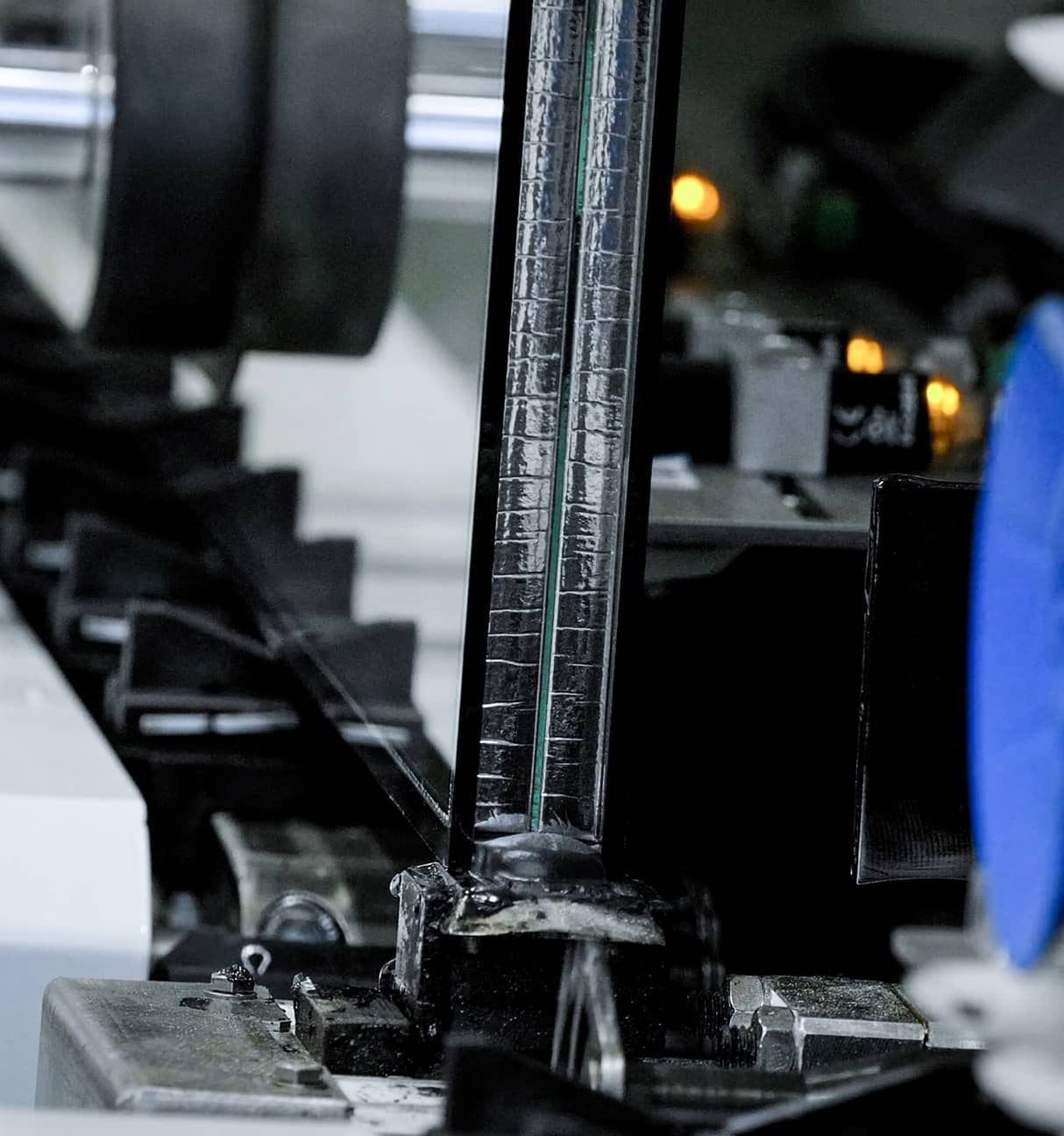

Edgetech partnered with leading machinery manufacturer Forel to deliver the step forward in energy-efficient glazing: a fully automated production line for thin triples – ultra-thin, triple-glazed insulating glass units that offer the performance of conventional triple glazed units without the weight, cost, and complexity.

And at the heart of the innovation is Edgetech’s market-leading flexible warm-edge Super Spacer®.

Eighteen months ago, Quanex approached Forel in Italy to work together on the encapsulation of a central thin pane of glass within a sealed unit, with the flexibility and precision of Super Spacer® allowing for the central pane to be assembled with sub-millimetre accuracy, ensuring structural integrity and thermal performance regardless of whether the centre pane is as thin as 1 mm.

This will allow IGU manufacturers to produce a triple glazed unit with a single outer seal, as in a double-glazed unit, rather than the traditional double sealing process.

“This is where we see the industry heading,” said Tony Palmer, Head of Sales at Edgetech. “Triple glazing is essential to futureproofing window systems against future thermal regulations and consumer demand. But until now, its widespread adoption in the UK has been held back.

“We believed the flexibility of Super Spacer® could be key in unlocking thin triples. As manufacturers of Super Spacer® we can provide a spacer that is fit for purpose for different cavities, whether the central pane is 1mm or 1.5mm – there aren’t any restrictions. We approached Forel because we knew they had the expertise to help make it happen, and it’s been incredibly exciting to work with them on this.”

The modified Forel High Speed Line, which was launched at Glassbuild 2024 and then presented to the UK market at the 2025 FIT Show following its G24 Award for Machinery Innovation, enables production of thin triples for high performance triple glazed units compatible with existing 70mm window systems so fabricators and installers don’t need to change how they operate.

Brian McDonald, CEO of Forel UK & Ireland, explained the decision to partner with Edgetech: “We’ve worked closely with Edgetech on numerous lines over the years, so we were delighted when they asked us to work with them on this. As a brand Edgetech have always led the way in innovation and together we’ve been able to bring a solution to market that could remove the final barriers to triple glazing adoption in the UK.”

With the first UK thin triple line expected to be operational by the end of 2025, the partnership between Edgetech and Forel marks a pivotal moment in delivering lighter, high-performance, and production-friendly triple-glazed IGUs.

For more information, visit www.edgetechig.co.uk

Please fill out the form below to a find a local supplier. Once we've found you closest suppliers you will be able to contact them all.

Your enquiry has been successfully submitted. You should receive an email or callback with 24-48 hours.

Return to the homepage